Production & Tech

Production

At Metal Group, our production process combines state-of-the-art technologies and skilled professionals. The process includes steel pipe cutting, welding, automated line, vacuum furnace, assembly line, quality checking, and laboratory testing. This allows us to deliver superior quality products with unrivaled reliability and efficiency.

Production Technology

Our production technologies at Metal Group are modern, efficient and highly advanced. We employ a combination of hardware processing, electrolysis, embossed stamping, 5D printing, laser engraving, surface finishing, stainless steel polishing/drawing and plastic spraying to ensure our products meet the highest standards. Our automated production line is operated by a team of experienced professionals, allowing us to quickly fulfill orders and provide superior quality products with unrivaled reliability.

- Stainless Steel Water Swelling Process

- Stamping

- Hardware processing

- Electrolysis

- Embossed stamp

- Finishing

Quality Assurance

We employ a rigorous quality assurance process to ensure our products meet the highest standards. This includes human inspection, machine vision recognition, salt spray (corrosion) tests, vacuum tests, and material tests. Each stage is monitored for consistency and accuracy, ensuring our products are of the highest quality.

- Human Inspection

- Machine Vision Recognition

- Salt Spray (Corrosion) Test

- Vacuum Test

- Material Test

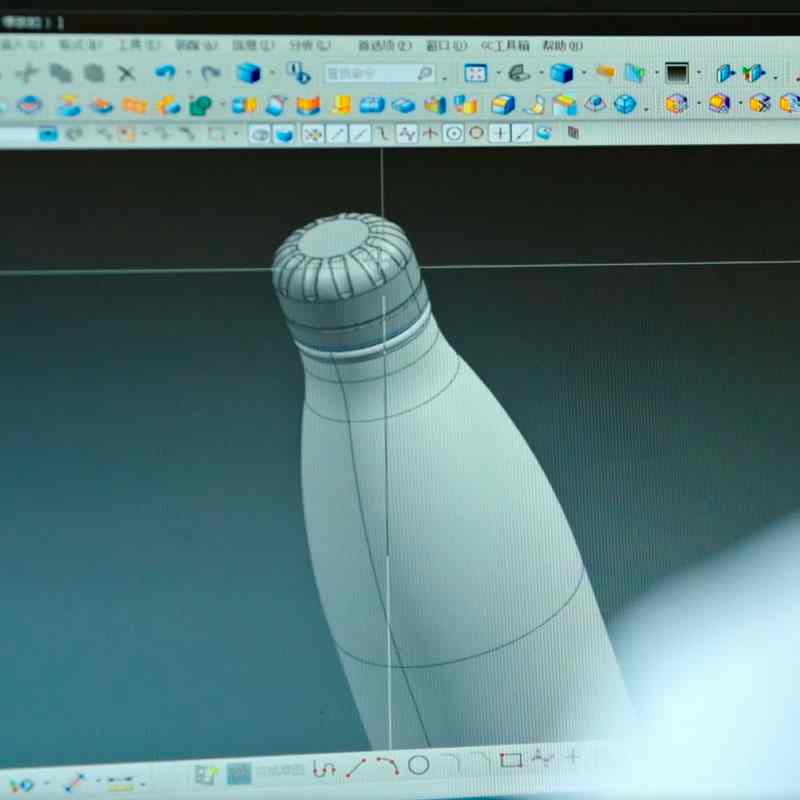

R&D

At Metal Group, we have an experienced Research and Development team dedicated to pushing the boundaries of product innovation. Our R&D process includes engineering modeling and mold development, allowing us to create customized products that meet even the most demanding requirements. Our skilled engineers constantly strive to develop cutting-edge technologies and provide our customers with the highest quality products.

Materials

We offer a variety of material options for our insulated bottles. Our stainless steel options include 201, 304, and 316, while our plastic parts include Tritan, PP, AS, and TPU. Each material offers different prices, levels of quality, and durability, ensuring that our customers can find a product that meets their needs and fits within their budget.

SUS 201

A type of austenitic stainless steel comprising 16% chromium, 3-5% nickel, and 1-2% manganese. It has more hardness, more susceptible to corrosion than the stainless steel in grade 304, and The surface is not as shiny as the stainless in grade 304. The durability of the stainless steel in grade 201 is relatively high.

SUS 304 (SUS 18/8)

SUS 304 material is the most commonly used stainless steel, containing 18% chromium and 8% nickel. It is food-grade stainless steel. It can maintain good strength and heat resistance in high-temperature and low-temperature environments and has good corrosion resistance, weldability, cold workability, and mechanical properties in a calm atmosphere.

SUS 18/10

SUS 18/10 is a type of austenitic stainless steel comprising 18% chromium and 10% nickel. It offers excellent corrosion resistance and is also suitable for food-related applications.

SUS 316

SUS 316 Stainless Steel contains 16% chromium, 10% nickel, and 2% molybdenum. It is surgical-grade stainless steel. Compared to SUS 10/18, it has better resistance to common acids and offers more flexibility for applications with different shapes. It is also more costly compared to the other materials.

Tritan

Tritan is a lightweight, durable, and recyclable plastic type.

PP

PP (Polypropylene) is a type of plastic resin that is lightweight and corrosion-resistant.

AS

AS (Acrylonitrile Styrene) is a thermoplastic polymer used in various applications due to its strength and flexibility.

TPU

TPU (Thermoplastic Polyurethane) is a strong and flexible plastic with excellent resistance to oil and chemicals.